Computer-aided design CAD Software Siemens Software

Table Of Content

It allows engineers to develop, test, and optimize their design in a safe environment, without having to build expensive prototypes. CAD software also provides a documentation trail, records specifications, and enables collaboration between multiple disciplines and stakeholders in product manufacturing. That is why organizations need to understand how computer-aided design works and its key concepts.

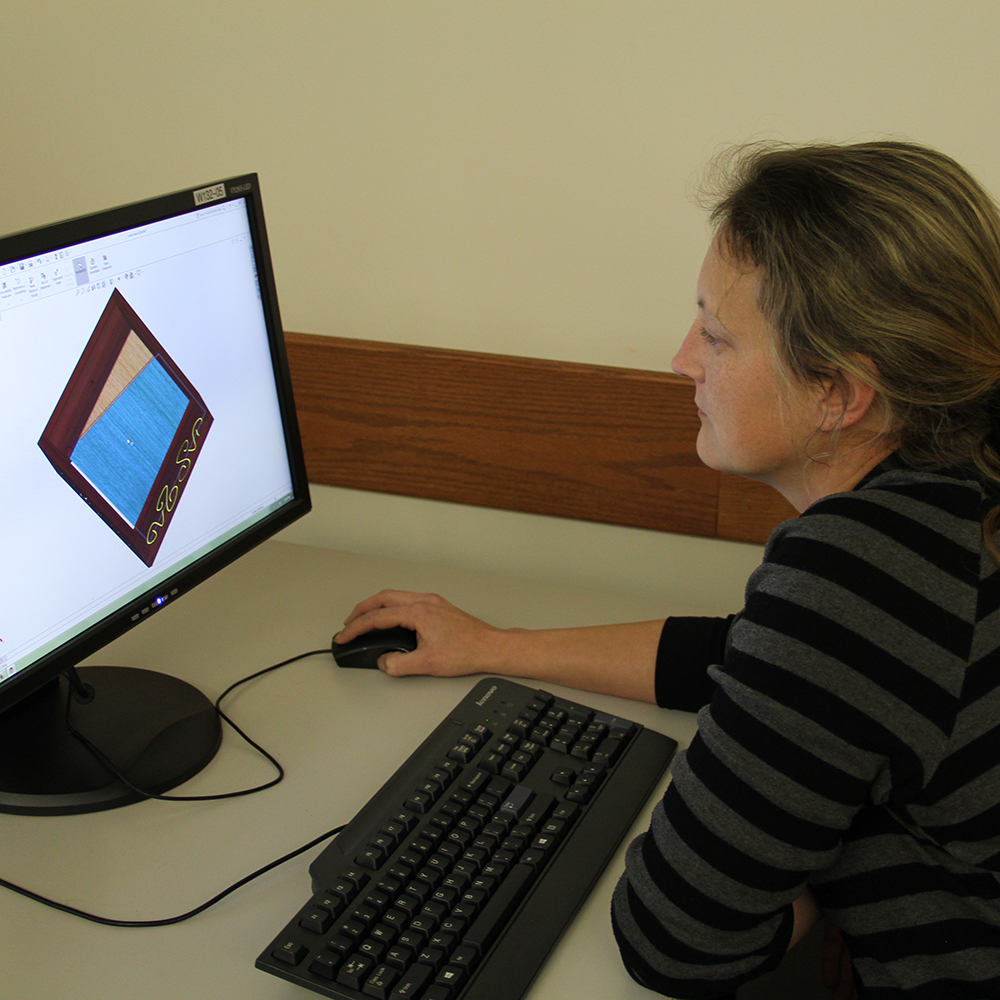

CAD Design

Site plans can include the footprint of buildings, landscaping designs, walkways, parking lots, drainage and water lines, and will show the placement of all of these items relative to one another. Designs can be created and edited in much less time, as well as saved for future use. CAD drawings are not limited to the 2D space of a piece of paper, and can be viewed from many different angles to ensure proper fit and design. Calculations are performed by the computer, making it much easier to test the viability of designs.

CAD for Student: The Best Options in 2024 - All3DP

CAD for Student: The Best Options in 2024.

Posted: Fri, 12 Apr 2024 07:00:00 GMT [source]

Types

Additionally, they convey how various components work together to form assemblies and offer crucial inspection locations. This indicates that the characteristics and relationships we feed into geometry, shape and size are controlled. If you use solid geometric modeling, which requires that you apply material first, the geometric will respond to forces similarly to real objects. A standard CAD system requires the installation of a CAD software package and, occasionally, a graphics card on your computer to work. The graphical user interface (GUI) is another crucial component of CAD software. When it comes to integrated electronics, it is critical that designers of both systems collaborate throughout the computer-aided design development process.

How is CAD used in architecture and construction?

This category of software can increase productivity, improve quality, and maximize organization by creating a documentation database for manufacturing. CAD software provides designers with the ability to create both 2D and 3D models. 2D models can be used for creating detailed drawings, while 3D models allow for more complex designs to be visualized and prototyped in a virtual environment. The ability to switch between 2D and 3D modeling within the same software is a key feature that saves time and improves accuracy. CAD software enables designers to create realistic and detailed visualizations of designs, which can help stakeholders better understand design concepts and features.

Nextech3D.ai Granted First in a Series of AI Patents for Generating 3D Models from Computer Aided Design (CAD) Data - GlobeNewswire

Nextech3D.ai Granted First in a Series of AI Patents for Generating 3D Models from Computer Aided Design (CAD) Data.

Posted: Wed, 13 Dec 2023 08:00:00 GMT [source]

These advantages mean CAD has had a huge impact on architecture, engineering, and construction, among other industries. As CAD allows for easy modification, documentation and collaboration, it is a far more precise, efficient and faster method than traditional manual drafting. CAD is used to create precise drawings and models of objects and structures, either in 2D or 3D. Today Cylwik regularly uses “a host of different CAD-related tools.” With their help, he can develop accurate models of something yet to be designed.

If so, make sure the software you get can open files from those CAD programs, but also saves or exports files in a format that those programs can open. There are a wide variety of uses for CAD software and the types of designs that can be made. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. CATIA from Dassault Systemes is a 3D product modeling and design tool used across multiple industries.

How has CAD technology evolved over time?

Another major factor to consider is the software's learning curve, or how easy it is to learn to use. The less time you spend learning a new software, the more designs you can create. The cost and time required to train users on a new CAD program must also be considered as well. The first thing to consider is what types of drawings and designs you will need the software for.

Automated product systems designer Technica International makes big gains in efficiency with Autodesk Product Design & Manufacturing Collection. CAD software pricing varies dramatically, from free versions to versions that cost thousands of dollars. Generally speaking, the higher the cost, the more robust the feature set will be. If a 2D floor plan is all you need, paying thousands for added 3D capabilities might be overkill.

What is STEM? Unlocking the World of Science, Technology, Engineering & Math

Our connected global construction platform unites all stakeholders on a project with unlimited access to support and a business model designed for the construction industry. It was described as the “first commercially available integrated, interactive graphics design, drafting, and manufacturing system." Approximately 9 out of 10 CAD programs find their roots in ADAM. AutoCAD is the industry-standard software used by most civil engineers and construction firms. Other commonly used software packages from Autodesk include Revit, Civil 3D and Fusion 360. Blueprinting is still widely used in various applications, but the original blueprint became obsolete primarily in the 1950s.

Blender, on the other hand, is a free and open-source 3D modeling software used in animation, visual effects, and game development. Computer-aided design, more commonly known as CAD, is the use of computers in the design process across a wide range of different industries. It is primarily used to create highly accurate 2D and 3D models, but CAD covers all steps in the design process, from creation and modification to analysis and design. Today, drawings/plans can be stored in the cloud, Thus, contractors have gained access to CAD-based drawings/plans at the worksite. Entire teams can check out plan modifications easily, including the general contractor and subcontractors.

They can include the size and location of ductwork, connections to control units, as well as the relationship and connections between various components. CAD modelers need a lot of training because they have to navigate complicated software. Data loss may occur while transferring models across software versions or systems due to compatibility problems. Software performance is impacted by hardware constraints such as sluggish processing speeds. These difficulties highlight the necessity of continual education, software upgrades, and hardware purchases to remove barriers and guarantee effective CAD modeling procedures. Given that its one of the oldest software categories on the market, there are a sizable amount of viable options available for free, including open-sourced programs.

Comments

Post a Comment